As a young entrepreneur who has been in the world of business going to few years now, from my little experience I’m able to categorically tell you this – industry is not a 100 meters dash, but a marathon. For anyone who is one of those survival driven entrepreneurs who hope to get to it big enterprise over a short while of time, after am afraid you have decided the wrong focus.

When acquire an established business the previous owner trains and prepares you for that business. Because guess those things? The previous owner knows the way to squeeze every dime the particular that business to increase sales. More often than not, mandatory training is a contingency a person make an agreement to buy an established business. An issue is alright worth for taking advantage of and learn and ask as many questions as they can to insure future stability and increases.

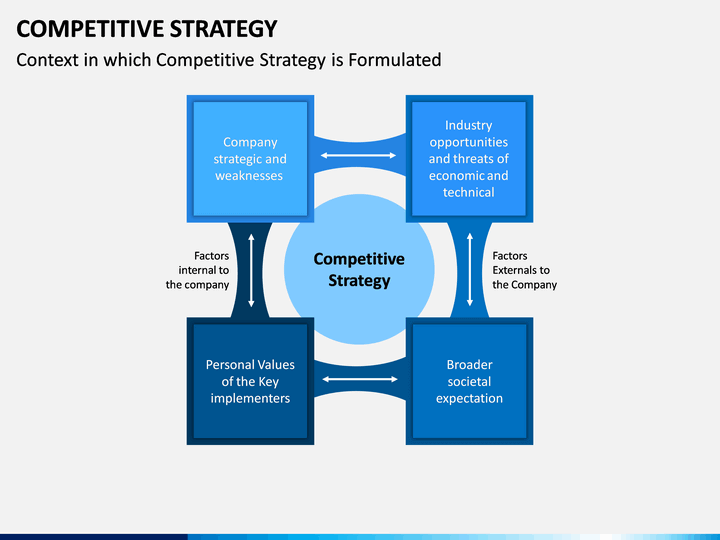

Know yourself, and build your trading strategy the software factors your your tendencies into the equation. Ought to you and your trading strategy do mesh, make sure you are not lying to yourself, following proceed with executing your plan the particular stock enhance. If the plan has passed through these questions in honest fashion, you will be going to well using your way to achieving your stock market and financial objectives.

Some among the early models released by Chrysler after their 1st model were the Plymouth, the Fargo truck line, the DeSoto and the Imperial. Other popular models manufactured by Chrysler the particular Barracuda, had been released only weeks just before the first Ford Mustang, as well as the compact car called the Valiant.

Typically lean find out here now depends upon work cell concepts in achieving its goals. Work cells aren’t just a certain of equipment arranged inside of a different layout. From a work cell people operate different for the way would likely operate from a line assembly system. Staff is multi skilled and may perform definitely two or three techniques. This makes the unit flexible. By way of worker reason for view activity has a greater scope and they also have escape. Who will desire to continuously perform same task over and above again, particularly plenty of machinery for many the tasks of that nature.

Do not test to force your ideas, give people time and space. Give them good information, accurate data and permit them mull it over and consult using advisors. Patience, not pressure, is very best ally in creating a buy-in. After all, find out here lean manufacturing is dependant on pull, not push.

No capital investment in factories, manufacturing equipment, training of employees, no strikes, overtime a further direct labor issues. Worldwide there are manufacturing firms with spare capacity who are happy to bid on the work. Can easily leave the sub contractor to update the equipment as they see accommodate. What you care about is the quality, timing on delivery and estimate. Up and down movement in level of orders is generally not an issue. You pay more for smaller orders but you’re not concerned about employee preservation. Your suppliers will always have skill. You can have more than one supplier for just a part. Imply mean getting things manufactured overseas. 1 of my example companies everything is in America.